PRODUCTS

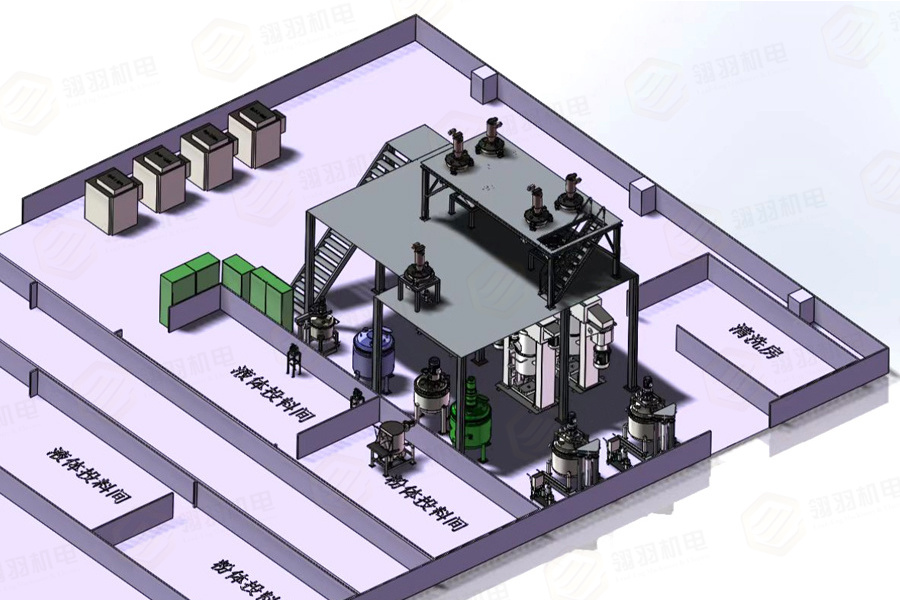

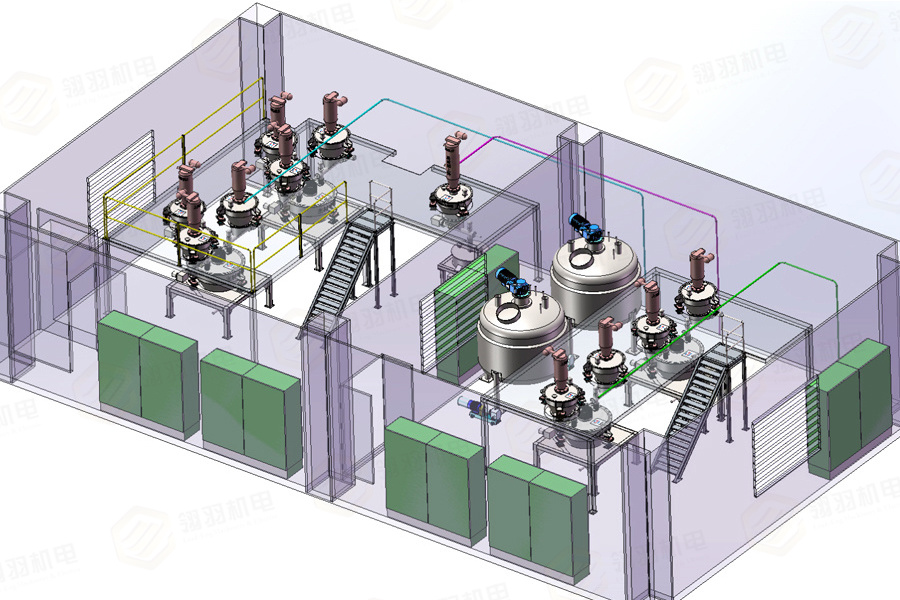

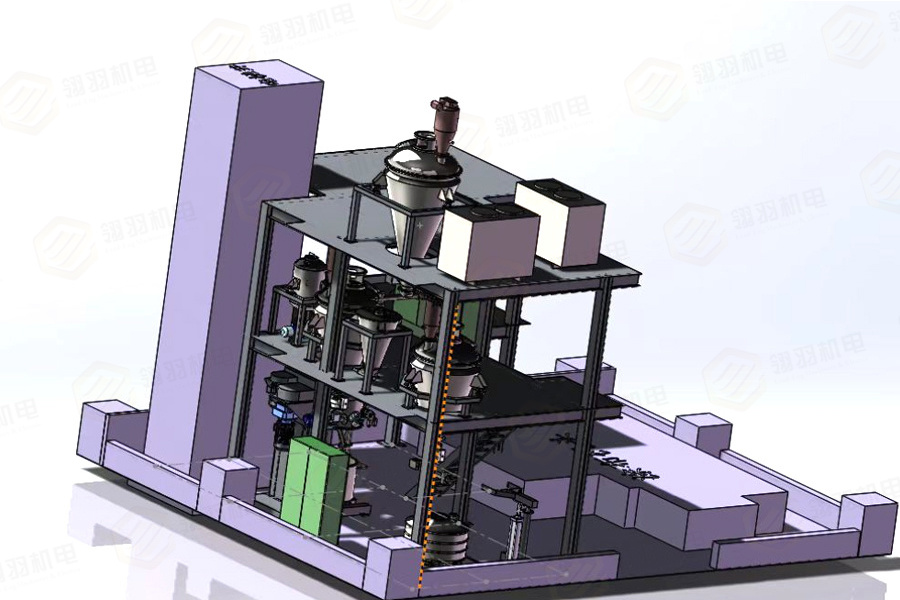

Complete system manufacturing base

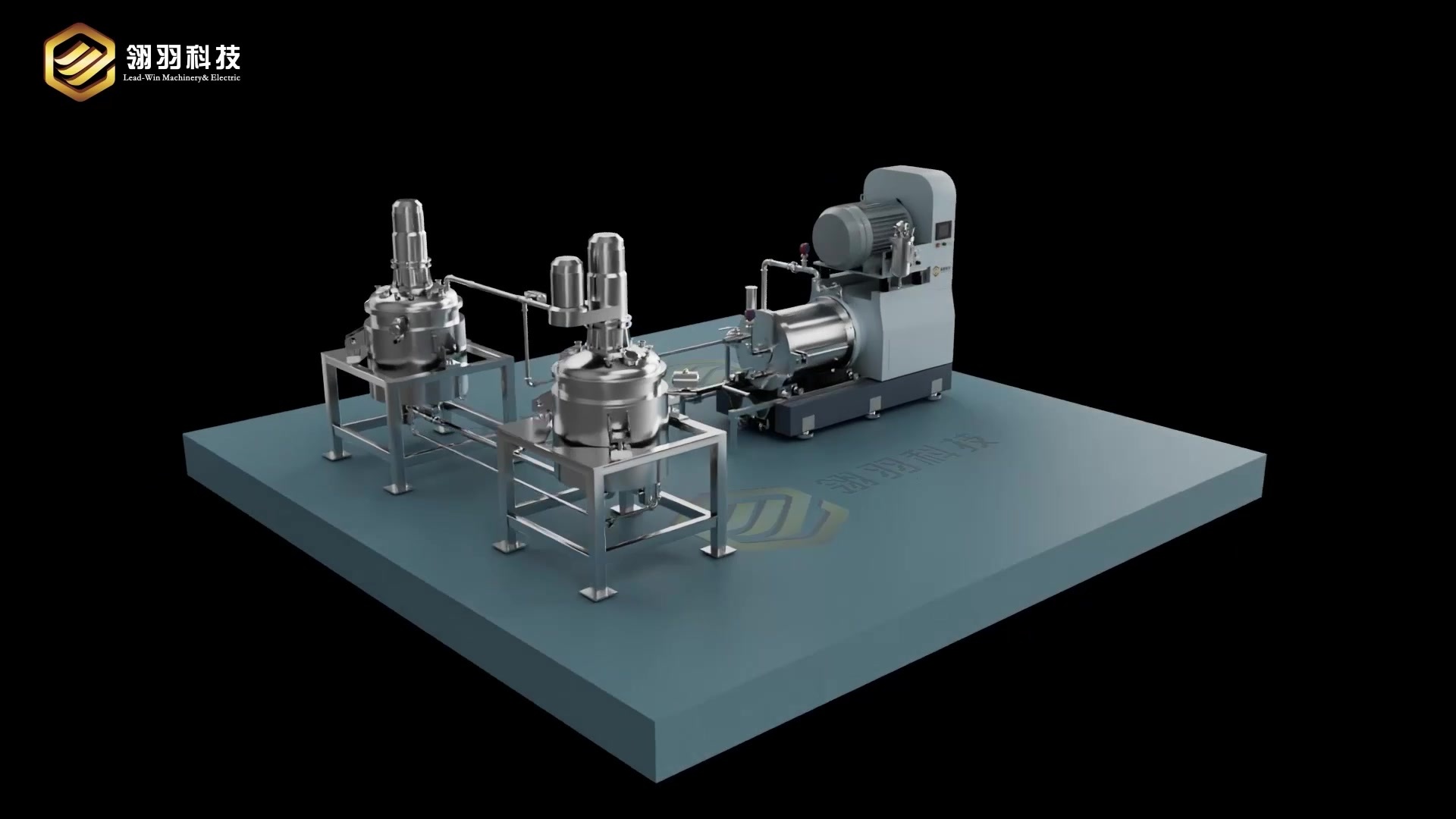

Sanding Machine

Blender

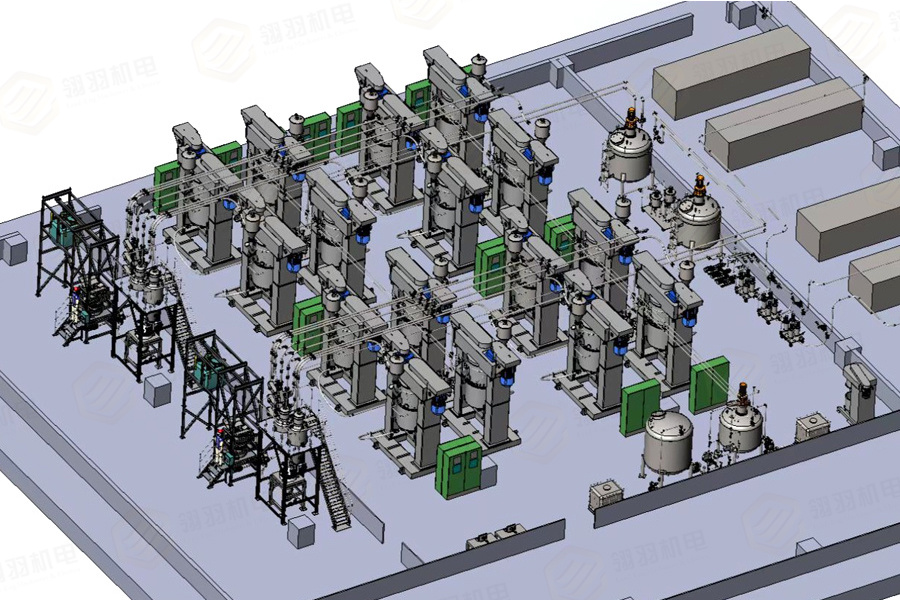

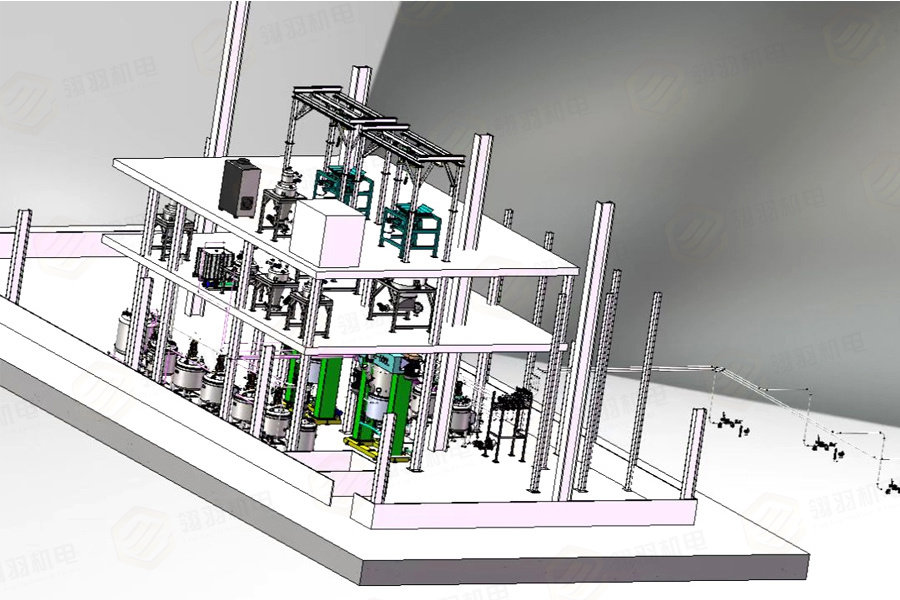

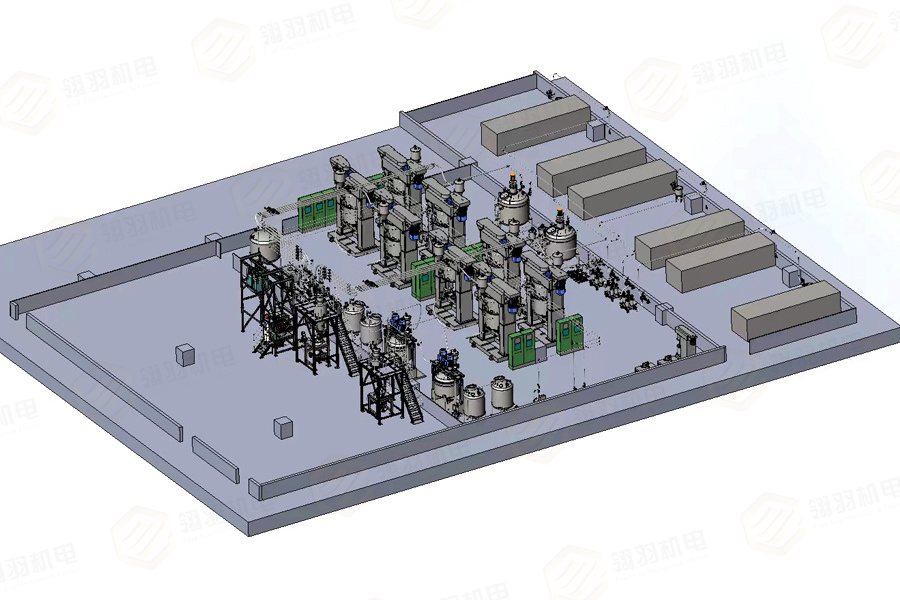

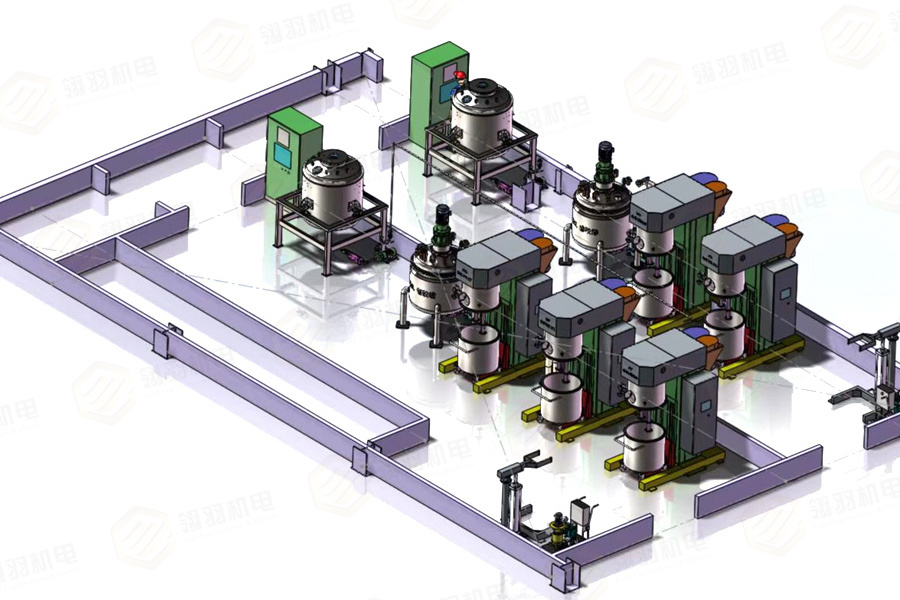

Production Line

Smart Factory

ABOUT US

Committed to the design of wet dispersion grinding production process

APPLICATION FIELD

It is applied in submicron and nanometer grinding fields such as various nanoscale powders, and has achieved wide market recognition.

NEWS

Understand company information, pay attention to industry trends in real time, we will provide you with accurate and reliable information